ISV | Focusing on the R&D, manufacturing, and application of vision products in intelligent manufacturing

ISV (AMTS 2018 booth No.W2-E01) strives to provide customers with complete vision solutions and its products contain inline geometric dimension measurement system, visual guiding system, glue inspection system, blue light 3D scanning system, gap & flush system, and defect detection system. As an independent competitive domestic brand, it becomes a supplier of dozens of domestic mainstream vehicle manufacturers, including SAIC-VW, SAIC-GM, and FAW-VW successively, and becomes the supplier nominated by SAIC-VW and SAIC-GM. In the meantime, ISV has established favorable partnership with CRRC, CSSC, CASC, and AVIC, supporting the large equipment manufacturing technology progress and product quality promotion with cutting-edge measurement technology.

On AMTS 2018, ISV will display:

Inline geometric measurement system

ISV’s inline geometric dimension measurement system is an inline non-contact measurement system based on vision inspection and laser measurement technology, which makes inline inspection of body in white and key components possible. The system breaks the restriction of traditional coordinate sampling inspection, monitors the body size variations on a real-time basis, and supports the improvement of production process in data.

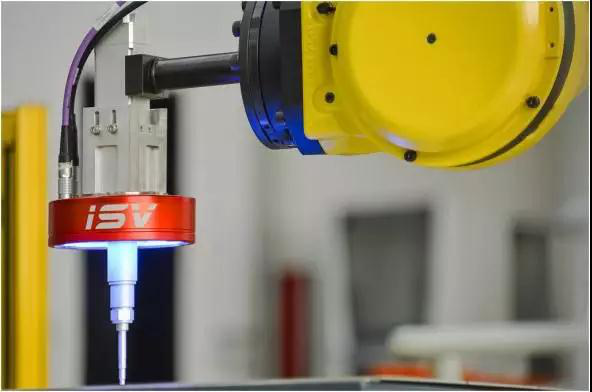

Visual guiding system

The visual guiding system combines the vision inspection technology with the industrial robot kinematic principle, aiming to act as “eyes” of the robot. It breaks the restriction that the robot can do nothing but repeat the demonstration trajectory and makes it possible to adjust the work trajectory in the real time according to pose variation of workpiece under operation, so as to improve the production efficiency and quality.

Several typical applications (including griping of work pieces on the appliance, automatic door mounting, body visual localization, and automatic windshield glass mounting) of visual guiding system in automobile manufacturing are displayed on this exhibition.

Glue Bead inspection system

ISV’s glue bead inspection system realizes the inline quality monitoring of glue technology. It detects the width, position, and continuity of adhesive tapes and issues real-time alarms to the glue quality strictly. The real-time detection system is fully integrated into the glue production process and highly integrated with the glue gun without occupying the tact time. The system is adapted to all types of tapes, and will not generate additional hardware costs to new vehicle models.

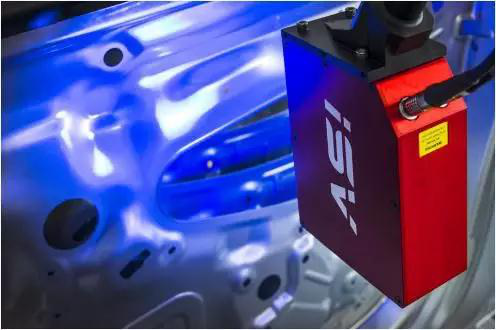

Blue Light Scanning system

ISV’s blue light scanning system, combining visual measurement with optical encoding and projection, realizes efficient acquisition of three-dimensional point clouds on free-form surface. Its one-time acquisition of high-precision and high-density three-dimensional point clouds breaks the traditional single-point sampling mode and could restore the true three-dimensional profile of measured object, greatly supporting product three-dimensional error comparison, digital simulation assembly, and model reversion.

The system, when combining with the industrial robot motion platform, can provide solutions for full automatic scanning and measurement of large components on complicated surface and realize the automatic scanning of auto body, airframe parts, etc.

Automatic (handheld) gap & flush system

ISV’s gap & flush system reflects the actual status of gap and flushness objectively with high-quality laser images and various algorithms, and realizes the matching quality detection of body covering parts.

The handheld gap & flush system, with embedded system, wireless transmission function, small size, and two configurable measurement modes, is suitable for the manual sampling inspection or full inspection on the production line.

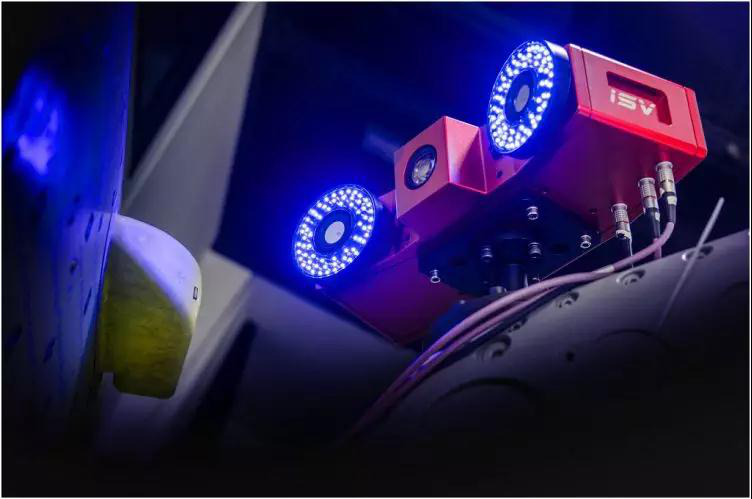

Laser welding lens inspection system

ISV’s laser welding lens inspection system, based on machine vision technology, realizes the lens surface defect detection. The system illuminates the tested lens uniformly with concentric light sources, acquires images with digital camera, judges the quantity, position and dimensions of the dead pixels on lens surface and reminds production personnel of changing the lens in time so as to guarantee the welding quality.